-

Table of Contents

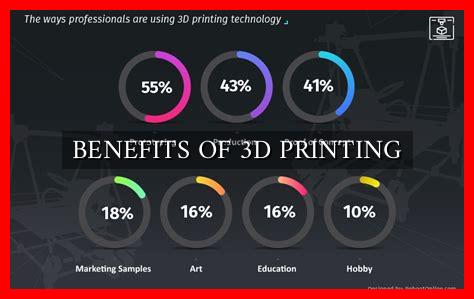

The Benefits of 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that has transformed various industries by allowing the creation of three-dimensional objects from digital files. This innovative process offers numerous benefits that have made it increasingly popular across different sectors. In this article, we will explore the advantages of 3D printing and how it is reshaping the way we design, prototype, and manufacture products.

1. Cost-Effective Production

One of the key benefits of 3D printing is its cost-effectiveness, especially for small-scale production runs. Traditional manufacturing methods often involve high setup costs and tooling expenses, making it impractical for producing small quantities of customized products. In contrast, 3D printing eliminates the need for expensive molds and tooling, allowing for on-demand production without incurring additional costs.

- Reduced material wastage

- Lower labor costs

- Increased design flexibility

2. Rapid Prototyping

3D printing enables rapid prototyping, allowing designers and engineers to quickly iterate and test their ideas. Traditional prototyping methods can be time-consuming and costly, requiring weeks or even months to produce a single prototype. With 3D printing, prototypes can be created in a matter of hours, accelerating the product development process and reducing time to market.

- Iterative design process

- Faster product development cycles

- Reduced lead times

3. Customization and Personalization

3D printing offers unparalleled customization and personalization capabilities, allowing for the creation of unique and tailored products. This level of customization is particularly valuable in industries such as healthcare, where personalized medical devices and implants can be produced to meet the specific needs of individual patients.

- Custom-fit products

- Personalized consumer goods

- Mass customization

4. Complex Geometries and Lightweight Structures

3D printing enables the production of complex geometries and lightweight structures that are difficult or impossible to achieve with traditional manufacturing methods. This capability has significant implications for industries such as aerospace and automotive, where lightweight components can improve fuel efficiency and performance.

- Topology optimization

- Complex internal structures

- Lightweight materials

5. Sustainability and Environmental Benefits

3D printing offers sustainability benefits by reducing material wastage and energy consumption compared to traditional manufacturing processes. Additive manufacturing can also enable local production, reducing the need for long-distance transportation and lowering carbon emissions associated with global supply chains.

- On-demand production

- Recyclable materials

- Energy-efficient manufacturing

Summary

3D printing has revolutionized the way products are designed, prototyped, and manufactured, offering a wide range of benefits across various industries. From cost-effective production and rapid prototyping to customization and sustainability, the advantages of 3D printing are reshaping the future of manufacturing. As the technology continues to evolve and improve, we can expect to see even greater innovation and adoption of 3D printing in the years to come.

For more information on the latest advancements in 3D printing technology, visit 3D Systems.