-

Table of Contents

Unlocking Success with 5 WHY 5 HOW

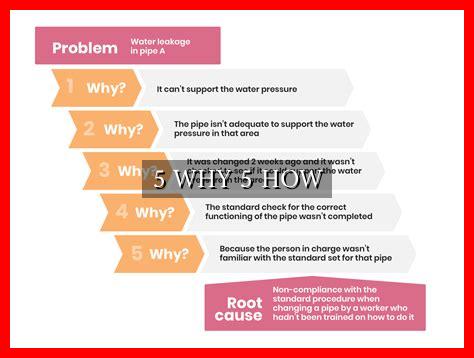

When it comes to problem-solving and continuous improvement, the 5 WHY 5 HOW technique has proven to be a powerful tool for organizations across various industries. This method, rooted in the principles of lean management and Six Sigma, helps teams get to the root cause of issues by asking “why” five times and then determining “how” to address them effectively. Let’s delve deeper into how this approach can drive success and foster a culture of innovation.

The Power of 5 WHY

The 5 WHY technique is a simple yet effective way to uncover the underlying reasons behind a problem. By repeatedly asking “why” five times, teams can peel back the layers of symptoms to reveal the root cause. Let’s consider an example to illustrate this concept:

- Problem: Production line downtime

- Why did the production line stop? (1st why)

- Because a machine malfunctioned.

- Why did the machine malfunction? (2nd why)

- Because it was not properly maintained.

- Why was it not properly maintained? (3rd why)

- Because there was no regular maintenance schedule in place.

- Why was there no regular maintenance schedule? (4th why)

- Because it was not considered a priority by the maintenance team.

- Why was it not considered a priority? (5th why)

- Because there was a lack of communication between the production and maintenance departments.

By asking “why” five times, the team was able to identify the root cause of production line downtime: a lack of communication between departments.

. This insight allows them to implement targeted solutions to address the issue effectively.

The Impact of 5 HOW

Once the root cause has been identified using the 5 WHY technique, the next step is to determine “how” to address the problem. The 5 HOW approach involves brainstorming and implementing solutions to prevent the issue from recurring. Let’s continue with our example:

- How can we improve communication between production and maintenance departments?

- Implement regular cross-departmental meetings to discuss maintenance priorities.

- Establish a shared digital platform for tracking maintenance schedules and updates.

- Provide training on the importance of communication and collaboration between teams.

- Assign a liaison role to facilitate communication between departments.

- Set up performance metrics to monitor the effectiveness of communication improvements.

By implementing these solutions, the organization can address the root cause of production line downtime and create a more efficient and collaborative work environment.

Real-World Applications

The 5 WHY 5 HOW technique has been successfully applied in various industries, including manufacturing, healthcare, and technology. For example, Toyota, a pioneer in lean management, uses this approach to continuously improve its production processes and drive innovation.

In healthcare, hospitals have adopted the 5 WHY 5 HOW method to enhance patient safety and reduce medical errors. By identifying the root causes of mistakes and implementing preventive measures, healthcare providers can deliver better quality care to their patients.

Similarly, tech companies like Google and Amazon leverage the 5 WHY 5 HOW technique to troubleshoot software bugs, improve user experience, and streamline operations. By fostering a culture of curiosity and problem-solving, these organizations stay ahead of the competition and drive growth.

Conclusion

The 5 WHY 5 HOW technique is a valuable tool for organizations seeking to drive continuous improvement, solve complex problems, and foster a culture of innovation. By digging deep to uncover root causes and implementing targeted solutions, teams can achieve sustainable success and stay competitive in today’s fast-paced business environment. Embracing this approach can lead to higher efficiency, better quality, and increased customer satisfaction. So, next time you encounter a challenge, remember to ask “why” five times and determine “how” to make things better.